Introduction

The integration of IoT (Internet of Things) and robotics is reshaping the future of manufacturing. Smart factories are no longer futuristic concepts—they are operational realities driving higher efficiency, precision, and sustainability. At Singleclic, we help industries across the Arab world embrace these digital transformations with tailored solutions that merge connectivity, automation, and intelligence.

What Role Does IoT Play in Smart Factories?

IoT in smart factories connects machines, sensors, and production systems to a unified digital network. This network continuously collects and exchanges data to enhance operational visibility and decision-making.

Key benefits of IoT in manufacturing include:

- Real-time monitoring: Instant insights into production lines, machine health, and resource utilization.

- Predictive maintenance: Prevent equipment failure before it happens using smart analytics.

- Data-driven efficiency: Optimize energy usage and reduce production waste.

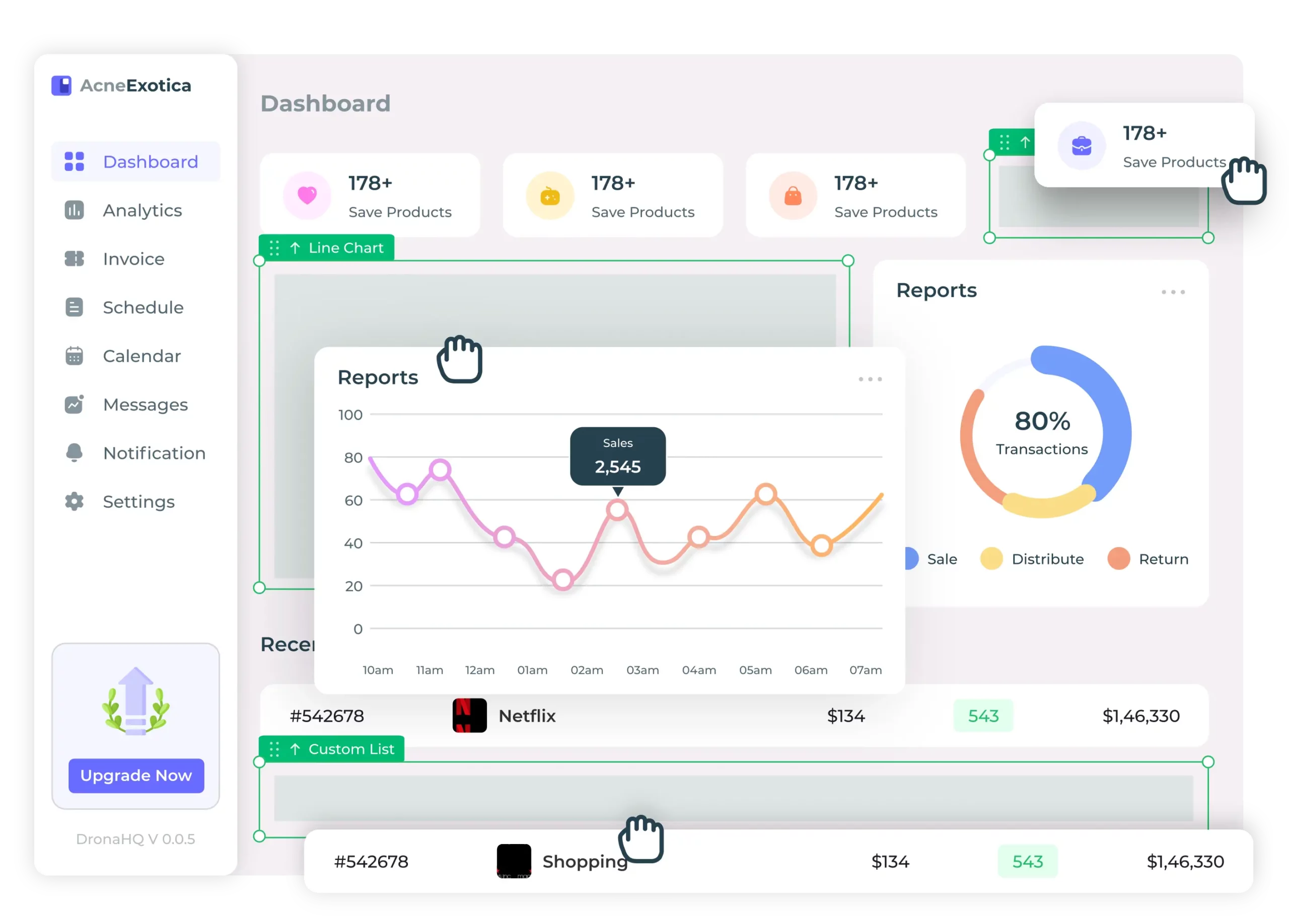

- Remote operations: Manage multiple facilities from a single dashboard.

By connecting every asset through IoT, manufacturers achieve unprecedented control and agility in their operations.

What Is IoT in Robotics?

IoT enables robots to “communicate” and collaborate intelligently. When robotics systems are connected via IoT platforms, they can:

- Share sensor data with other devices in real time.

- Adjust to environmental changes dynamically.

- Coordinate tasks with minimal human supervision.

- Improve safety and accuracy in repetitive or hazardous environments.

This connectivity allows robots to operate autonomously while staying aligned with the overall production strategy—a core principle of smart manufacturing.

What Is Smart Manufacturing in IoT?

Smart manufacturing refers to the use of connected technologies—IoT, robotics, AI, and cloud computing—to create intelligent production ecosystems.

IoT provides the foundation by enabling:

- Interconnected systems: Machines and devices work as part of a larger digital ecosystem.

- Adaptive production: Systems respond automatically to changes in demand or supply.

- End-to-end traceability: From raw materials to finished products, every step is monitored and recorded.

This digital backbone transforms traditional factories into smart factories, where automation meets intelligence.

What Is the Role of Automation and Robotics in Smart Factories?

Automation and robotics are the driving forces behind smart factories. They reduce human error, speed up production, and improve product consistency.

Their roles include:

- Assembly and precision tasks: Robots handle repetitive work with micro-level accuracy.

- Material handling: Automated guided vehicles (AGVs) streamline logistics and warehouse management.

- Quality control: Vision-based robots inspect products and detect defects faster than human eyes.

- Collaborative robots (cobots): Work alongside humans safely to enhance flexibility on production lines.

Together with IoT, robotics ensures factories become adaptive, self-learning, and sustainable.

Singleclic’s Role in Building Smart Factories

Since 2013, Singleclic has been a trusted technology partner for industrial innovation across the Arab region.

We deliver integrated digital solutions that empower manufacturers to build and scale smart factories:

- Software Development: Custom ERP, CRM, and low-code platforms for digital transformation.

- Network Solutions: Design, installation, and maintenance of industrial network infrastructure.

- Cybersecurity: Protecting factory systems and data from cyber threats.

- Cloud & Hosting Services: Reliable, scalable, and secure cloud-native deployments.

- 24/7 Technical Support: Continuous monitoring and technical assistance to ensure uptime.

With expertise in IoT, robotics, and automation, Singleclic helps enterprises modernize their production landscapes and lead the Industry 4.0 revolution.

Conclusion

The synergy between IoT and robotics is the foundation of the smart factory revolution. These technologies enable manufacturers to achieve greater flexibility, reduced downtime, and real-time insights—all crucial for staying competitive in the digital age.

Partnering with Singleclic means joining the future of intelligent, connected manufacturing.

📞 Contact Singleclic

- Phone: +2 010 259 99225 / +971 42 475421 / +966 58 1106563

- Website: https://singleclic.com/

- Email: info@singleclic.com

🚀 Empowering the Arab world’s industries through innovation, connectivity, and automation.