Meta Description:

Discover the top technologies shaping the future of manufacturing in 2025 — from AI and IoT to robotics and digital twins. Learn how Singleclic empowers industrial transformation across the Arab world.

🌐 Introduction: The New Era of Manufacturing

The manufacturing industry is undergoing a massive digital transformation driven by advanced technologies that merge physical and digital worlds. Today, smart factories, connected machines, and real-time analytics are not futuristic ideas—they’re reality.

As a leading IT solutions provider since 2013, Singleclic has been helping manufacturers across the Arab world adopt innovative tools to boost efficiency, reduce costs, and achieve sustainable growth.

🔍 What Is the Future of Manufacturing?

The future of manufacturing lies in intelligent automation, data-driven decisions, and human–machine collaboration.

Companies are shifting from traditional linear production lines to smart, adaptive ecosystems where machines communicate, learn, and optimize operations automatically.

Key Drivers:

- Increased demand for customization and flexibility

- Global supply chain disruptions highlighting automation needs

- Sustainability goals and energy efficiency

- Integration of AI and data analytics into daily operations

⚙️ Emerging Technologies Transforming Manufacturing

Let’s explore the core technologies driving this revolution and their real-world impact.

🧠 1. Artificial Intelligence (AI) and Machine Learning (ML)

AI helps manufacturers predict machine failures, optimize production schedules, and reduce waste.

With Machine Learning algorithms, factories can learn from performance data to continuously improve output and quality.

➡️ Example: Predictive maintenance powered by AI reduces downtime and saves millions annually.

🌐 2. Internet of Things (IoT)

IoT connects machines, sensors, and devices to share real-time data.

This visibility enables remote monitoring, efficient asset tracking, and energy management.

Singleclic’s IoT integration helps manufacturing plants achieve smarter control over production lines and equipment.

🦾 3. Robotics and Automation

Modern robotics are more intelligent, collaborative, and cost-effective.

From precision assembly to autonomous logistics, robots are redefining productivity.

They enable “lights-out” manufacturing—plants that run 24/7 with minimal human supervision.

🧩 4. Digital Twins

A Digital Twin is a virtual replica of a physical asset or process.

Manufacturers use it to simulate operations, predict outcomes, and plan maintenance before issues arise.

This minimizes errors, shortens product development cycles, and improves performance.

☁️ 5. Cloud Computing and Edge Technologies

Cloud-based platforms allow global teams to collaborate and analyze massive datasets securely.

Meanwhile, Edge Computing brings real-time analytics closer to the production floor, reducing latency.

Singleclic provides reliable cloud hosting and distributed infrastructure for seamless industrial operations.

🛡️ 6. Cybersecurity and Data Protection

With greater connectivity comes higher vulnerability.

Cyberattacks targeting factories can disrupt operations or steal intellectual property.

Singleclic’s cybersecurity solutions protect manufacturing networks with firewalls, endpoint protection, and real-time monitoring.

🧪 7. Additive Manufacturing (3D Printing)

3D printing enables faster prototyping and small-batch production, reducing time-to-market.

It’s ideal for industries like aerospace, automotive, and healthcare that demand high precision and customization.

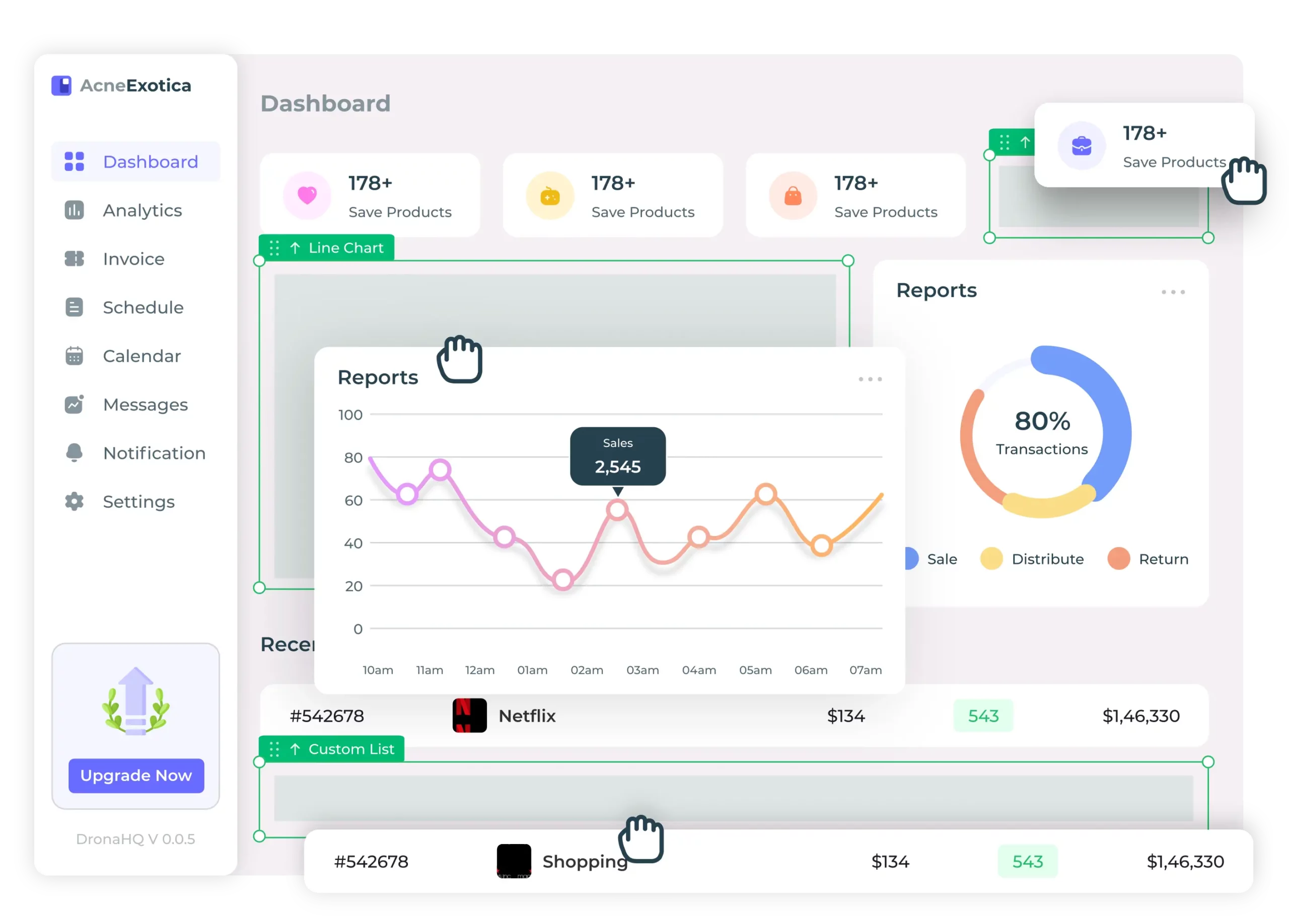

💡 How Technology Impacts Manufacturing

Technology impacts manufacturing by:

- Enhancing operational efficiency

- Reducing human errors

- Lowering production costs

- Improving product quality

- Enabling data-driven decision-making

By embracing digital transformation, manufacturers gain agility and competitive advantage.

🤖 What Will Manufacturing Look Like in the Next Decade?

By 2035, fully autonomous factories will become the norm.

Technologies like AI, IoT, digital twins, and robotics will combine to create self-learning, sustainable ecosystems.

Human workers will focus more on creativity, innovation, and supervision, while machines handle repetitive tasks.

🏢 How Singleclic Powers Manufacturing Transformation

Since 2013, Singleclic has empowered industrial clients across Egypt, Saudi Arabia, and the UAE with cutting-edge digital solutions.

Our Services Include:

- Software Development: ERP, CRM, and Low-Code automation tools

- Network Infrastructure: Secure, scalable industrial networking

- Cybersecurity: Multi-layer protection for connected systems

- Cloud & Hosting: High-availability hosting for enterprise apps

- Technical Support: 24/7 professional support

📞 Contact Us:

Egypt: +2 010 259 99225

UAE: +971 42 475421

KSA: +966 58 1106563

🌍 https://singleclic.com/

🧭 Conclusion: Embrace the Smart Future of Manufacturing

The future of manufacturing belongs to innovators who combine technology with strategy.

By adopting AI, IoT, digital twins, and cloud computing, industries can achieve a new level of intelligence, agility, and efficiency.

Partner with Singleclic to lead your factory into the next industrial revolution — Industry 4.0 and beyond.

🔎 People Also Ask (for SEO snippet optimization)

Q1: How does technology impact manufacturing?

A: It increases efficiency, automation, and data-driven decision-making while reducing human errors and costs.

Q2: What will be the future of manufacturing?

A: A fully digital, connected, and sustainable ecosystem where AI and automation dominate.

Q3: What are the 10 emerging technologies in manufacturing?

A: AI, IoT, robotics, digital twins, 3D printing, cloud, blockchain, AR/VR, cybersecurity, and nanotechnology.

Q4: What are the new technologies in manufacturing?

A: Intelligent automation, smart sensors, predictive maintenance, and digital twin integration.